Kontakt oss

Snarveier

Hjelp

Nyhetsbrev

Meld deg på vårt nyhetsbrev og hold deg oppdatert på nyheter fra Norsonic.

- © 2024 Norsonic

- Personvern

- Laget av NYG

Her er resultatet av våre kunders ønsker!

Et bærbart akustisk kamera med lav vekt, god oppløsning og mulighet til også å måle og analysere lave frekvenser.

128 mikrofoner – 46 cm.

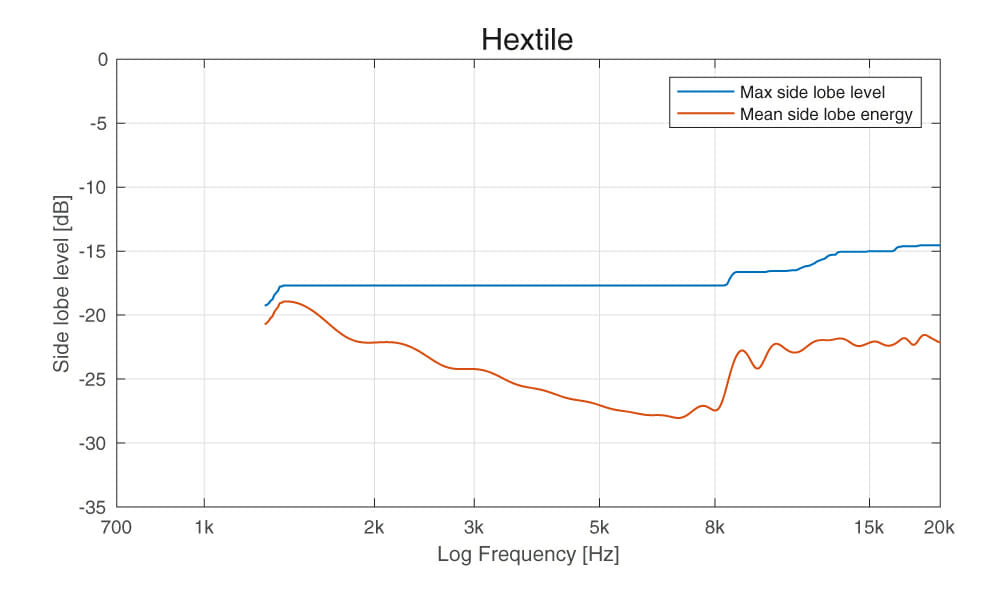

Med en Hextile har brukeren et lite, bærbart og lett akustisk kamera som kan brukes til et bredt spekter av målesituasjoner. Systemet kan monteres på stativ eller brukes håndholdt.

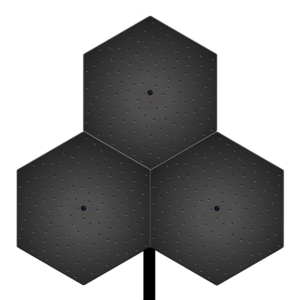

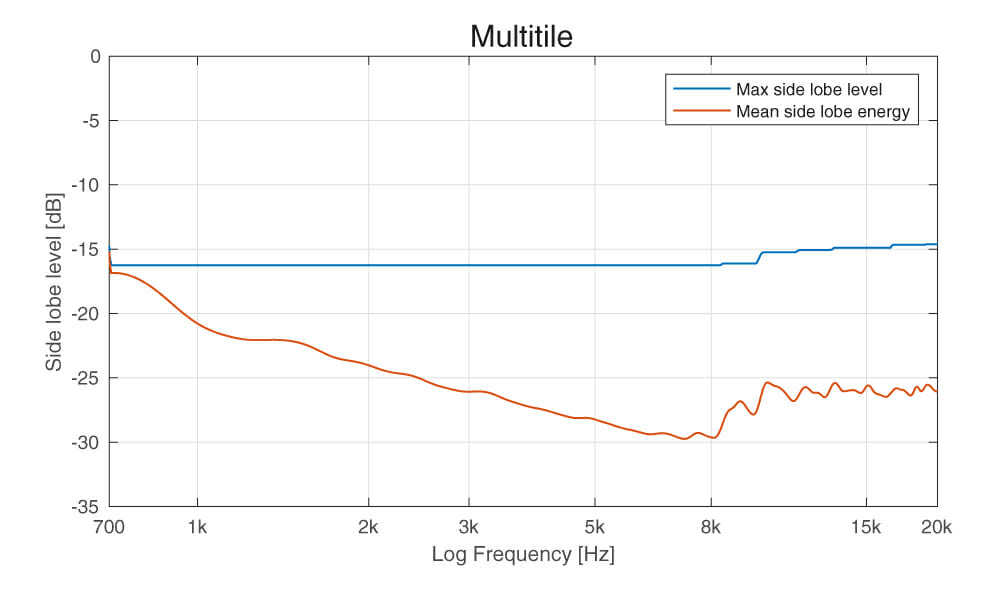

384 mikrofoner – 96 cm.

For brukere som ønsker optimal oppløsning for å kunne analysere flere lydkilder parallelt i et bredt frekvensområde, kan tre hextiles enkelt kombineres til et kraftig multitile akustisk kamera.

Multitile – great resolution

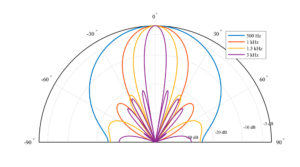

Array geometry and beampattern for Multitile

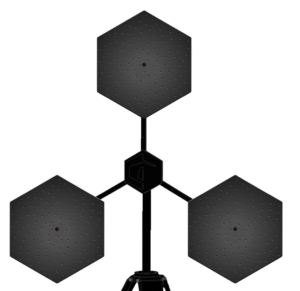

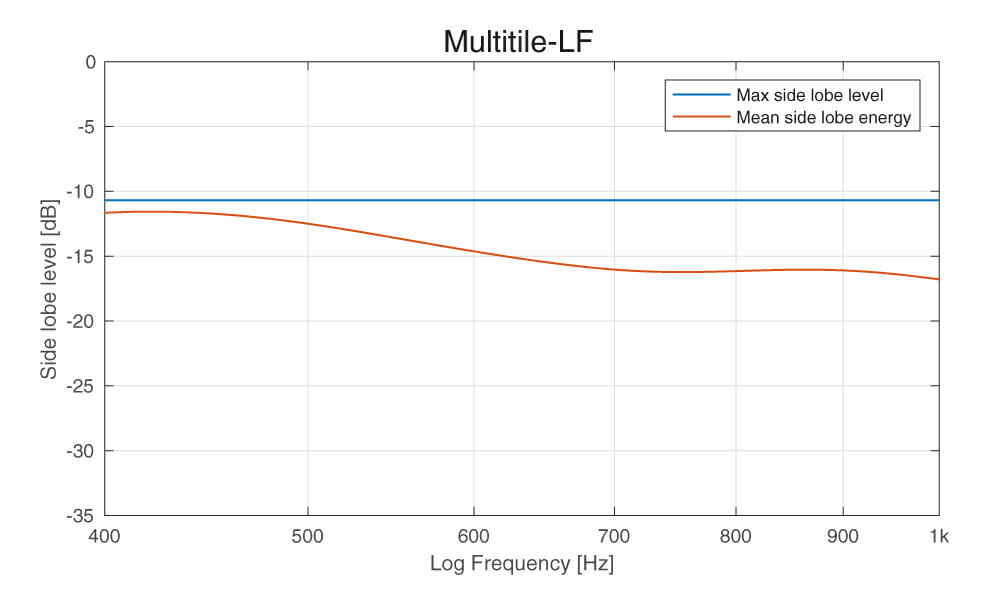

384 mikrofoner – 146 cm.

Ved å plassere tre Hextiles lenger fra hverandre, økes den maksimale diameteren til hele systemet, noe som gjør det ideelt for måling av lavfrekvente lydkilder – Genialt!

Multitile (LF mode) – Low frequency measurements

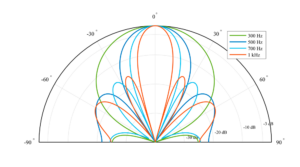

Array geometry and beampattern for Multitile (LF mode)

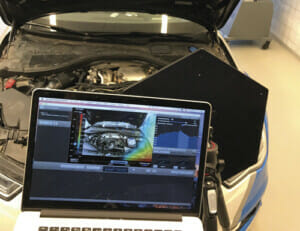

The software design strategy has always had user friendliness and ease of use in mind. We want the user to be able to get results quickly, and start analysing recordings easily, thus spending time on the analysis, rather than the measurement set up or configuration of parameters. Live view of measurements combined with an intuitive software interface enables users without prior experience to make measurements within the first five minutes after powering the device.

The one feature that really sets the software apart is the virtual microphone. The virtual microphone enables the capability to only get audio signals from the chosen listening point, and listen to sounds coming from specific directions of the video image, while suppressing noise and sounds emitting from other positions than what is selected. With this tool the user has the power of super hearing, and may gain more insight in addition to regular colour plotting of sources. Such super hearing may be especially useful in noisy and complex sound environments, where for instance different noise sources greatly impair the ability to distinguish which machinery is producing a faulty noise.

In addition to live plotting and directive listening, it is also possible to record measurements and do the analysis at a later time. The raw signal from all microphones are then saved, and all parameters such as frequency selection, time selection and so on can be changed in post-processing. This means that a recording can be done without selecting the optimal parameters during the measurement, since these can be changed when analysing the recording. This also means that anybody can do the actual recordings themselves since it is then basically a matter of pointing the array roughly towards the area of interest and pressing record. All analysis and changes of parameters can be done in post-processing such as directive listening, graphical overlay of sources, spectrogram, FFT analysis and so on.

Sometimes sources may be closely spaced apart, or a strong noise source in the area of interest is interfering with the recording and impairing the image quality. Often this will be seen as either a single large source, or the source of interest will be completely shadowed by the stronger source. Seen in the image below is a situation where two equally strong sources are positioned close to one another, and the resulting colour plot will display a single large source. In such situations the acoustic eraser feature may prove valuable. This function will add a red circle to the screen that can be dragged to any point, and remove the source from that point. This is highly effective when several noise sources are present. As seen on the pictures the acoustic eraser completely removes the source where the suppress point button is positioned. The virtual microphone can further be positioned on the source of interest.

Especially in automotive applications RPM measurements may give vital information. The acoustic camera software has the possibility to display frequency content as a function of RPM by using the order analysis function.

Especially in automotive applications RPM measurements may give vital information. The acoustic camera software has the possibility to display frequency content as a function of RPM by using the order analysis function.

In the spectrogram window, frequency as a function of RPM is plotted. It is further possible to select a square in the spectrogram window to isolate interesting events. By pressing the “apply” button on the selection, the RPM and frequency limits in the main view window automatically change to the limits set by the selection in the spectrogram. The user may then find and interesting sound event in the spectrogram, and automatically get the corresponding colour plotting of the event chosen.

Connection: USB

Microphones: 128 MEMS microphones

Max sound level: 120 dB

Min sound level (system): 9 dBA

SNR per microphone: 65 dBA

SNR array (system): 82 dBA

Audio sampling rate: 44.1 kHz

Camera resolution: 2592 x 1944

Opening angle: 105°

Frame rate: 15 FPS

Operating temperature range: -40 to +85

Per microphone (flat): 100 Hz – 20 kHz

Per microphone: -26 +/-3dBFS/Pa @1 kHz 94 dB

Spatial sensitivity Hextile: 410 Hz – 20 kHz

Spatial sensititivy Multitile: 220 Hz – 20 kHz

Spatial sensititivy Multitile (LF mode): 120 Hz – 1 kHz

Dimension Hextile: 41 cm x 48 cm, Ø 48 cm

Dimension Multitile: 83 cm x 84 cm, Ø 96 cm

Dimension Multitile (LF mode): 126 cm x 121 cm, Ø 146 cm

Weight Hextile: < 3 kg

Weight Multitile: < 10 kg

Material: Aluminium

Power consumption: < 3 W

The biggest improvement when going from a single Hextile to the two different Multitile configurations is best demonstrated on a low frequency source. Seen below are the results from recordings on a single omnidirectional noise source emitting pink noise, with the colour plotting being done when the input signals are filtered at 500 Hz. This should give a direct comparison of the low frequency capability of the different arrays.

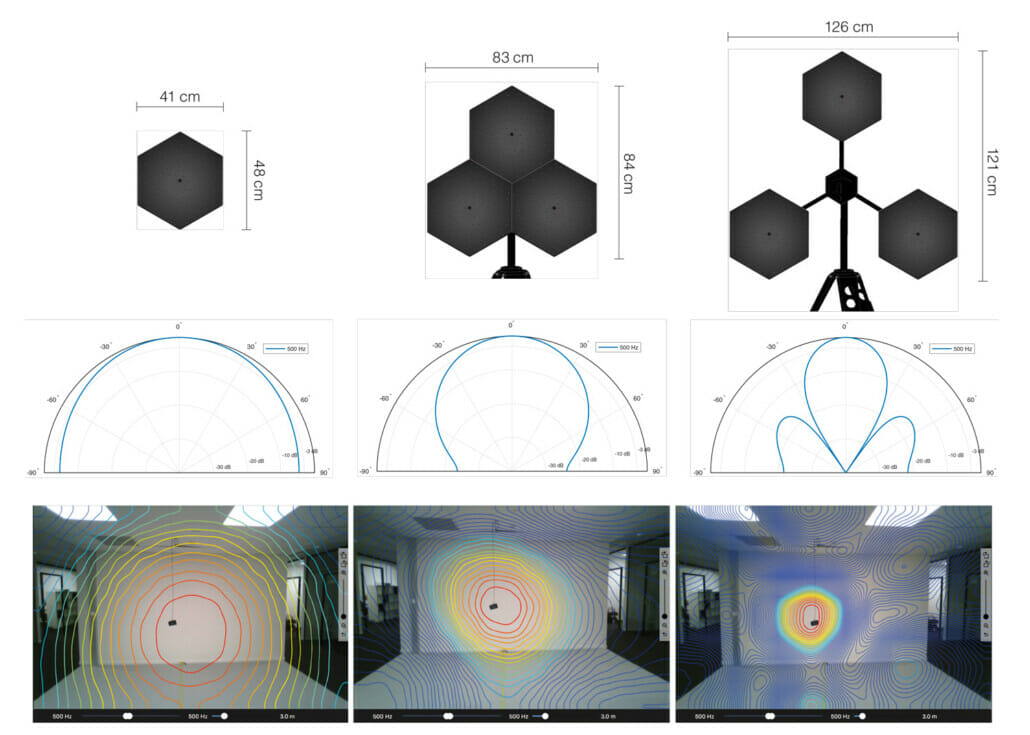

At the top are the different array configurations used for the recordings, with a 128 element Hextile, a 384 element Multitile, and a 384 element Multitile (LF mode). The diameters of the array configurations are 46 cm, 96 cm, and 1.46 m respectively.

The second rows show the beampattern for the different array configurations at 500 Hz and 3 dB dynamic range. As can be seen the beampattern gets more narrow, thus giving better resolution, as the overall array size increases.

Lastly the plotting results from the three different array configurations recorded on a real noise source are shown with 3 dB dynamic. The improvement in terms of resolution and pin-pointing the source is clearly visible when using bigger equipment.

Array geometry, beampattern at 500 HZ, and plotting results of pink noise source for Hextile, Multitile and Multitile (LF mode)

Norsonic Acoustic Camera

Filming sound leakages in highly reflective office environment

Measurements in office complex, Lier, Norway, April 2016

Norsonic Acoustic Camera

Filming breakout noise from café and concert venue

Measurements in bar and bistro in Oslo, Norway, March 2016

Norsonic Acoustic Camera

Measuring impact of traffic noise in apartment living room

Measurements in apartment Oslo, Norway, February 2016

Norsonic Acoustic Camera

Wall leakage testing in the lab with acoustic camera

Measurements in acoustic lab, England, November 2015

Norsonic Acoustic Camera

Using acoustic camera inside caravan car to find squeak and rattle noise

Measurements in caravan car, Lier, Norway, October 2015

Norsonic Acoustic Camera

Filming low-frequency structure born noise with acoustic camera

Measurements in apartment building, Oslo, Norway, September 2015

Norsonic Acoustic Camera

Identifying short time high pitch squeak noise from electric window in car door

Measurements in car factory, Korea, July 2015

Norsonic Acoustic Camera

Pinpointing low level sanitary noise in apartment building

Measurements in apartment building in Oslo, Norway, April 2015

Norsonic Acoustic Camera

Finding acoustical weak points in room dividing modular walls

Measurements in a conference hotel in Trondheim, Norway, November 2014

Norsonic Acoustic Camera

Identifying low-frequency tonal noise in windy and noisy conditions

Measurements on LNG gas terminal in Stavanger, Norway, September 2014